Hydrogen Production

In our extensive array of filtration solutions, we cater to various hydrogen production methods, including hydrogen production electrolysis. Our absolute pleated filters play a crucial role in maintaining the integrity of high purity water, a vital component in hydrogen production. These AFP Series filters are designed to prevent solid contamination, offering a large filtration area, high flow rates, and an impressive dirt holding capacity. They are available with absolute filtration ratings ranging from 0.6 to 120 µm. Additionally, Mott provides a range of coalescers that are instrumental in removing oil and water content from gas streams. This is especially important in the production of hydrogen, as it protects compressors and significantly reduces maintenance costs. We offer a complete line of filtration solutions for both liquid and gas applications, which are essential for enhancing operational efficiency in hydrogen production processes. These solutions are available upon request.

Questions? Call 860.747.6333 Today!

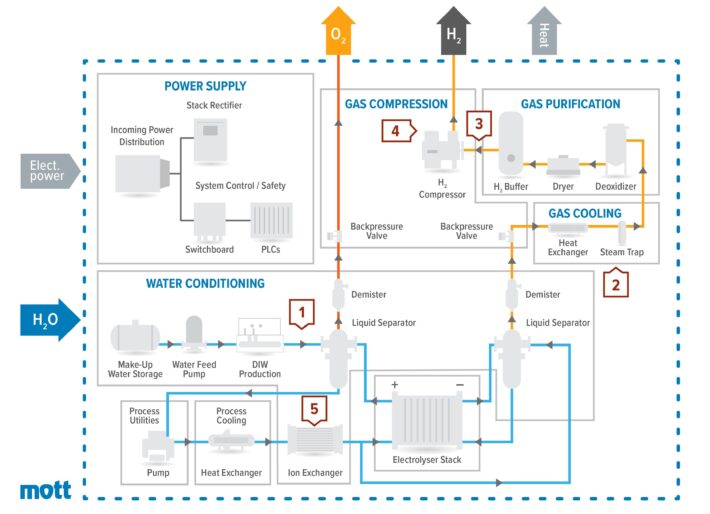

Product Applications Overview in Hydrogen Production System

ASCO Filtri AFP Absolute Filter Pleated Cartridges

1. Essential for hydrogen production methods, these cartridges are designed to protect and prevent solid contamination in high purity water, a critical component in hydrogen production processes.

ASCO Filtri Gas Liquid Coalescer Type GLP Series

2. Upstream Deoxidation: Plays a pivotal role in hydrogen production electrolysis by preventing deactivation of catalysts or molecular sieves.

3. Upstream H2 Compressor: Crucial for reducing water content to the lowest quantity physically achievable (< 0.01 ppm), enhancing the efficiency of hydrogen production.

4. Downstream of the Compressor: Integral for removing oil content in gas streams, a vital step in maintaining the purity of hydrogen in production.

ASCO Filtri Special SS Housings

5. These elements are fitted in high-quality SS vessels, featuring special elements with SS wire mesh, suitable for robust applications in hydrogen system environments.

Related Resources

Typical Applications

- Hydrogen Production

- Renewable Energy

- Electrolysis

ASCO AFP Pleated Cartridges

ASCO AFP Series Pleated Cartridges are used for protecting and preventing solid contamination of high purity water in the process of hydrogen generation.

ASCO GLP Series Gas-Liquid Coalescers

The GLP series gas-liquid coalescer elements are manufactured with a series of high performance micro fiberglass, polypropylene, polyester or nylon coalescing media in a pleated configuration optimized for liquid separation.

Gas Diffusion Layers

Mott porous metal gas diffusion layers are the leading choice for high performance electrolyzer and fuel cell applications.

Porous Transport Layer (PTL) Case Study

Mott Porous Transport Layers achieve high power densities in gas generation applications due to a proprietary ultra-thin design resulting in better mass transport and a smaller footprint.

Lab & Engineering Services

Discover our entire range of services, including rapid prototyping, filter feasibility, media characterization and more.

Explore Mott's Capabilities

Provides an overview of markets served, applications, products, materials, and engineering capabilities.

Innovative Hydrogen Production Electrolysis Technology

Hydrogen production, involving the generation of hydrogen gas, is crucial in numerous industrial applications and emerging clean energy technologies. It’s central to fuel cell technology, industrial processes, transportation, and power generation, playing a key role in shifting towards a sustainable, low-carbon energy future. Notably, hydrogen can be produced through various renewable sources, including water electrolysis powered by renewable electricity, which is a prime example of hydrogen production methods.

Mott excels in the field of hydrogen production, leveraging its deep expertise in porous metal and filtration technology. Our products, including filters and coalescers, are meticulously crafted to ensure the highest purity and reliability of hydrogen gas. This is particularly significant in hydrogen production electrolysis, where maintaining the purity of hydrogen is essential. Mott’s commitment to innovation and precision engineering positions us at the forefront of supporting the efficiency and sustainability of hydrogen production processes. Our dedication to providing top-tier solutions makes us a valued ally in the journey towards a cleaner energy future.

FAQs: Production of Hydrogen

Q: What role does Mott play in hydrogen production?

A: Mott specializes in providing key components, including filters and coalescers, essential for the hydrogen production process. Our products ensure the efficiency and purity of hydrogen, particularly in methods like electrolysis.

Q: Does Mott produce hydrogen filters specifically?

A: No, Mott does not manufacture “hydrogen filters” as such. Our focus is on producing components like filters and coalescers that are critical in the hydrogen production process, ensuring high purity and operational efficiency.

Q: How do Mott’s products contribute to hydrogen production?

A: Our products, including pleated filters and gas-liquid coalescers, are designed to prevent contamination and maintain the purity of hydrogen. This is crucial in applications like fuel cell technology and renewable energy sectors.

Q: Can Mott’s filtration technology be used in hydrogen production via electrolysis?

A: Yes, Mott’s filtration technology is well-suited for hydrogen production through electrolysis. Our filters play a vital role in maintaining the purity of water and gases used in this process.

Q: Are Mott’s filtration solutions customizable for different hydrogen production applications?

A: Absolutely. Mott offers a range of customizable filtration solutions to meet the specific requirements of various hydrogen production methods and applications.

Q: How does Mott ensure the quality and reliability of its products?

A: Mott is committed to innovation and precision engineering. We conduct rigorous testing and quality control measures to ensure that our products meet the high standards required in hydrogen production processes.

Q: What makes Mott a preferred partner in the hydrogen production industry?

A: Mott’s extensive expertise in porous metal and filtration technology, combined with a commitment to sustainability and innovation, makes us a trusted partner in the hydrogen production industry. Our solutions are designed to enhance efficiency and support the transition to a low-carbon energy future.