Industrial Hemp Production

Photo: Hemp Industries Association

By Michael Lewis , NCAT Sustainable Agriculture Specialist; and Jody McGinness Executive Director, Hemp Industries Association

Abstract

This publication explains that industrial hemp is an agricultural crop grown for grain seed and fiber and introduces several important considerations, given the regulations that govern hemp production in the United States. It explores a variety of uses for hemp and provides production information, as well as further resources.

Introduction: What is Industrial Hemp?

The term industrial hemp commonly refers to cannabis varieties that are grown primarily as an agricultural crop for grain seed and fiber. The plant was grown as a commodity fiber crop in the United States from the mid-18th century until the mid-1930s and was reintroduced with the passage of the 2018 Farm Bill, which defined “hemp” as any variety of the plant Cannabis sativa L. with a delta-9-tetrahydrocannabinol (∆9 THC) concentration of 0.3% or less on a dry weight basis. This definition includes all parts of the plant, its seeds, extracts, isomers, cannabinoids, and other derivatives, whether the plant is growing or not (Congressional Research Service, 2019). Industrial Hemp is dioecious, possessing separate male and female plants with distinctive growth characteristics.

Table 1. Products Derived from the Hemp Plant

| Fiber | Grain/Seeds | Flower | |

| Plant Material | Stalks (bast fibers and hurd/core fibers) | Dried seeds (oil and protein) | Dried and cut (flower bud, floral material) |

| Common Uses | Bast fibers for paper, insulation, composites, and textiles; core fibers for animal bedding, concrete, fiberboard, oil absorbents | Foods and body products Shelled seed and fines Oil and seed cake |

Extractions of plant resin (CBD, other cannabinoids) Nutraceuticals and wellness products |

Regulatory Considerations

Disclaimer: There is a shared state/Tribal-federal regulatory structure governing hemp cultivation and production, with some states and Tribes implementing their own plans and others utilizing USDA’s (USDA AMS, 2022). Carefully and thoroughly review the procedures, licensing and reporting requirements, and other regulations specific to the state or Tribe with jurisdiction in the area before developing and implementing your hemp planting plan (National Conference of State Legislatures, 2020).

Licensing, Testing, and Compliance

States and Tribes require farmers to be licensed under the terms of their respective state plans, and to test samples of their crop for ∆9 THC concentration within 30 days pre-harvest, using a licensed testing facility. Check with your chosen testing facility for sampling procedures. States and Tribes also provide guidelines for the disposal of non-compliant, or “hot” crops. For more specifics on this, farmers should consult their State Departments of Agriculture for regulatory clarity.

Harvest Timing

A major consideration in industrial hemp production is the harvest window. There is a 30-day allowed harvest window that begins on the date of the final regulatory test required for compliance. This can create logistical challenges, due to the labor-intensiveness of harvesting and drying such a heavy and moist crop.

Genetics

The selection of genetics is an important and often difficult process for producers when factoring in the THC threshold for compliance with federal regulations, which is .3% THC. Grain and fiber producers will have less of an issue, as other developed countries have been producing industrial varieties of hemp for grain and fiber for decades, and a significant number of certified varieties exist already. Cannabinoid producers will find sourcing stable and consistent varieties more difficult, as breeding for cannabinoid content in hemp plants is in its infancy. Most states will provide producers with a list of approved varieties that have the likelihood of remaining compliant, but there is still no guarantee for a compliant crop. Considering that a crop exceeding the maximum THC thresholds will need to be destroyed, genetic research is one of the most important aspects of hemp production when a producer is targeting cannabinoids.

Market Challenges

A variety of regulatory factors unique to industrial hemp create an uncertain environment for producers. In the United States, hemp is a young and volatile market. Producers should carefully identify which hemp product(s) and sales channels are available before starting production, secure any necessary permits prior to production, and ensure that production is done in accordance with state and federal laws. The lack of historical research or agricultural data and the scarcity of current market information on pricing and demand create additional challenges for potential producers. This situation means there are several things for producers to consider:

- Dual oversight of states and Tribes, along with the federal government, creates a lack of clarity for producers.

- The status of cannabis at the federal level is continually evolving and has an impact on the overall regulatory climate.

- Misconceptions among local law enforcement and local jurisdictions have and will continue to hinder producers’ abilities to market their crops.

Local Ordinances

When planning your production, it is important to check for any state or local ordinances that will have an impact on your operations. Some counties and communities have made the production of hemp illegal, as it could cross-pollinate local medical or recreational cannabis crops. It is just as critical to understand your local regulations as your state and federal guidelines.

Hemp Uses

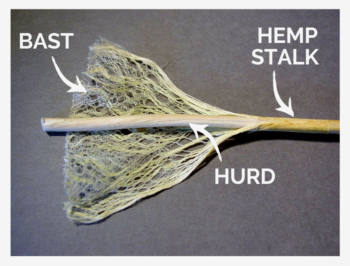

Bast Fiber

Hemp has been grown as a bast-fiber crop for centuries. It produces a long, durable fiber that is strong, absorbent, and anti-microbial. Around 14% of the plant material is comprised of bast fiber.

Uses:

- Rope/cordage

- Insulation

- Textiles

- Bioplastics

Hurd Fiber

The soft core of the hemp stalk (hurd) is light, dust-free, and highly absorbent.

Uses:

- Concrete/hempcrete

- Animal bedding

- Fiberglass

- Paper

Hemp Seed

Hemp seeds are a great source of plant proteins and contain all nine essential amino acids. The seeds, technically nuts, can be eaten raw or used to make milk, oil, cheese substitutes, or protein powder.

Uses:

- Food

- Alcohol

- Biofuels

- Livestock feed

- Oil paint

- Plant-based protein

Hemp Flower

Hemp flower is typically harvested from unpollinated female plants. The flowers contain hundreds of cannibinoids and terpenes that are extracted from the plant using various methods, including distillation.

Uses:

- 130+ cannibinoids (CBD, CBG, CBN, etc.)

- Pharmaceuticals

- Nutraceuticals

- Consumables

Hemp Production

Table 2: Hemp Production Specifications by Use

| Fiber | Grain/Seeds | Flower | |

| Planting Density | Seeding rate of 45 to 80 pounds per acre | Seeding rate of 25 to 40 pounds per acre | Transplant-production style, 1,600 to 2,000 plants per acre |

| Physical Characteristics | Tall plants with thin stalks and less leafy material | Plants with small branching stalks and more leafy material | Bushy (female) plant with wide branching to promote flowers/buds |

| Harvest Height | 10-18 feet | 6-9 feet | 4-8 feet |

| Yields | 2+ tons per acre | 1,200+ pounds per acre | 1,000+ pounds per acre |

| Post-harvest Handling | Retting

Baling Storage |

Cleaning

Drying Storage |

Trimming

Drying Storage |

Grain Production

Spacing

There are roughly 30,000 hemp seeds per pound. Like other seed crops, hemp is direct-seeded at a rate of 25 to 40 pounds per acre. The exact row spacing depends upon the producer’s existing equipment. At closer spacing (7”), the plants will develop a fast, tight canopy that will help reduce weed pressure, while a wider spacing (30”) will allow for mechanical cultivation of weeds early in the season. The plant matures in 110 to 120 days, and harvest occurs when 65 to 70% of the seed has matured.

Harvest

Hemp grain is harvested with traditional combines that have some minor modifications related to tine spacing. When contracting a hemp grain crop, it is advised to check with the buyer for specific combine settings. The harvested grain will need to be cleaned and moved into a dryer within six hours of harvest to reduce chances of spoilage. Most seed cleaners will work adequately, and it’s common to use conventional aerated grain bins. The ideal moisture content for storage is 8 to 9%.

Considerations

The floral material of the hemp plant contains a significant quantity of resinous substances that can cause equipment to stick and bind. It is important to check and clean the heads on a regular basis to prevent damage to equipment and the crop.

Fiber Production

Spacing

Hemp fiber crops are planted at a rate of 40 to 80 pounds per acre and sometimes higher, depending upon the desired fiber quality. The exact row spacing depends upon the producer’s existing equipment. At close spacing (7”), the plants will develop a fast, tight canopy that will help reduce weed pressure, while a wider spacing (30”) will allow for mechanical cultivation of weeds early in the season.

Tighter spacing promotes a more upright growth habit. This produces longer, higher-quality bast fibers. Harvest of hemp fiber plants begins when around 15% of the plants are flowering.

Harvest

Most hemp-fiber producers are utilizing disc mowers, sickle-bar mowers, and haybines. When using a haybine, it is best to open the conditioner as wide as you can to help prevent crimping the fibrous hemp stalks. Most fiber crops will need to be retted in the field. Retting is the natural decomposition of the stalk, which helps separate the inner hurd and outer bast fibers. This is typically performed in windrows. The retting process takes between two and six weeks, depending on climate conditions. After proper retting, the hemp fibers are baled and stored for shipping to a processor.

Considerations

Hemp is a long and strong fiber that can be rough on equipment. Long fibers tend to bind in cutting and baling equipment. There is also a lack of processing infrastructure in the United States, which makes marketing fiber crops difficult in some regions.

Cannabinoid (CBD) Production

Spacing

Unlike grain and fiber, production of industrial hemp for cannabinoids is considerably more labor intensive and includes a significant increase in risks. Plant density for cannabinoid production is between 1,000 and 2,500 plants per acre. Production is more horticultural in nature, and, typically, female plants are mechanically transplanted. The lower-density planting allows for plants to grow bushier, and the lack of pollen from males will increase the cannabinoid content of the plant.

Photo: Anna Carson Dewitt

Harvest

Harvest of plants for cannabinoid production takes place between 90 and 120 days from transplant, when the cannabinoid content is highest. Regular testing as the plants reach maturity is critical to ensure attaining the maximum CBD content while still meeting the THC threshold of below .3%. While there is some development of mechanized harvesting equipment, most producers still hire laborers to hand harvest and trim the floral material from the stalks. Each processor has specific standards for delivery of plant material, but most require the material to be dried to an 8 to 12% moisture content. Drying of the floral material is most often accomplished by hanging plants in barns, like tobacco.

Considerations

It is important to understand the specifications of the processor to ensure a viable crop. Producers will need to determine whether they will utilize clones, seedlings, or feminized seedstock for their production needs. Each of these options has positives and negatives that need to be factored into the decision-making process. Direct-seeding feminized seedstock can be costly, and spring rains and moisture can create issues with damping off, a fungal disease of the seeds and young plants. Clones will provide more uniformity in the plant structure and cannabinoid content, but they can be costly and tend not to set a strong taproot. As such, they require more effort and care when grown outdoors. Growing from seedlings will produce a strong taproot, which will help in nutrient uptake and provide healthier plants, but the plants will be less uniform and subject to genetic instability.

Another consideration in CBD production is weed management. The spacing of plants will allow significant weed pressure and a plan must be in place to handle this. Currently, production is split between plasticulture and mechanical or hand cultivation.

Irrigation and fertigation are also important considerations. When growing for cannabinoids, the plants tend to require more nutrient inputs and regular irrigation cycles. Most producers currently use low-pressure drip irrigation to address this challenge.

Summary

The production of industrial hemp represents both opportunity and risk for producers. The sundry products that can be created from the crop represent multiple marketing opportunities for producers, and the plant can fit into most types of diversified systems without much modification. While this crop is exciting and represents significant opportunities for producers, it is still a relatively new crop that still requires significant research and market development before it can be adopted as a widespread agricultural crop. Producers are encouraged to exercise caution when planning to introduce this crop into their systems and be aware that the newness of this old crop still provides significant risk in production and marketing.

Industrial Hemp Production By Michael Lewis , NCAT Sustainable Agriculture Specialist; and Jody McGinness Executive Director, Hemp Industries Association

Published October 2022

© NCAT

IP 627

This publication is produced by the National Center for Appropriate Technology through the ATTRA Sustainable Agriculture program, under a cooperative agreement with USDA Rural Development.